Services

Our SERVICES

We are committed to providing our customers with exceptional service while offering our employees the best training.

Ceramic Insulation Systems

Roof & Building Envelope Coatings

Piping & Process Equipment Insulation

Tank & Vessel Insulation

HVAC, Duct & ID Fan Insulation

Corrosion Under Insulation (CUI)

Energy-Saving Insulation Retrofits

Insulation Removal & Replacement

Ceramic Insulation Systems

High-performance ceramic coatings that cut heat transfer and protect assets—delivered with exceptional service and durable, cost-effective solutions that don’t add bulk

Application: Thin-film coating installs fast with minimal clearance issues and no heavy wrap or lagging.

Heat Control: Reduces surface temperatures and heat loss for safer touch points and better energy use.

Protection: Hydrophobic and UV-resistant to help block moisture, corrosion, and weathering.

Uptime: Rapid cure options shorten downtime and speed return to service.

Inspection: Smooth finish makes visual checks and maintenance easier vs. thick insulation.

Use Cases: Ideal for hot piping, vessels, OEM skids, and difficult geometries.

Roof & Building Envelope Coatings

Seamless elastomeric/silicone systems that stop leaks, reflect heat, and extend roof life—backed by our quality materials and expert installation.

Restoration: Re-cover aging roofs without costly tear-off to reclaim service life.

Waterproofing: Monolithic membrane seals seams, fasteners, penetrations, and parapets.

Energy: High reflectivity lowers heat gain and can reduce HVAC load.

Compatibility: Bonds to metal, BUR, mod-bit, and single-ply when prepped to spec.

Standards: FM/ASTM-tested assemblies and manufacturer systems available.

Warranty: Eligible manufacturer and workmanship warranties when specified.

Piping & Process Equipment Insulation

Code-compliant thermal and personnel-protection insulation for hot and cold lines, fittings, and equipment—installed right the first time.

Design: Proper thickness and materials selected per process temperature and duty.

Jacketing: Aluminum/SS/PVC finishes sized and sealed for indoor/outdoor service.

Access: Removable/reusable covers for valves, pumps, and strainers to speed maintenance.

Condensation: Correct vapor barriers and seams to control sweating and reduce CUI risk.

Efficiency: Cuts energy loss and stabilizes process temperatures for better throughput.

Sanitation: Washdown-ready options for food, pharma, and clean mechanical spaces.

Tank & Vessel Insulation

Custom systems for vertical/horizontal tanks that stabilize product temps, prevent sweating, and lower operating costs—built for durability.

Configuration: Panel or blanket builds tailored to tank geometry and supports.

Weatherproofing: Tight cladding and sealed joints for reliable outdoor performance.

Cold Service: Prevents moisture, icing, and product temperature swings.

Hot Service: Provides personnel protection and heat retention on high-temp tanks.

Access: Clean details around nozzles, manways, and gauges for safe serviceability.

Engineering: Anchors, standoffs, and penetrations designed to spec.

HVAC, Duct & ID Fan Insulation

Thermal/acoustic treatments that improve efficiency, cut noise, and stop condensation—keeping systems clean, quiet, and reliable.

Coverage: Supply/return ducts, plenums, housings, and air handlers insulated to spec.

Condensation: Correct vapor barriers and seams to prevent sweating and dripping.

Acoustics: Lining/lagging options reduce fan and equipment noise.

Cleanability: Smooth, durable jacketing that withstands routine maintenance.

Best Practices: Built to SMACNA/ASHRAE guidance for performance and safety.

Hardware: Proper hangers, adhesives, and seals for long-term hold.

Corrosion Under Insulation (CUI) Prevention

Inspection, remediation, and barrier systems that stop moisture ingress and shut down CUI—protecting assets before damage spreads.

Assessment: Targeted cut-backs, NDE, and spot checks to map corrosion risk.

Surface Prep: SSPC/NACE-grade prep and coatings for lasting protection.

Materials: Hydrophobic insulation, sealed joints, and correct metal selection.

Moisture Control: Vapor stops, drip edges, and drainage details at transitions.

Replacement: Damaged lagging and cladding removed and rebuilt to spec.

QA/QC: Documented photos, DFT readings, and as-found/as-built reports.

Energy-Saving Insulation Retrofits

Targeted upgrades that pay back quickly—reducing heat loss/gain, stabilizing processes, and lowering utility spend with verifiable results.

Audit: Energy survey with estimated savings, payback, and ROI modeling.

Thickness: Add-on insulation sized to current standards and service temps.

Fixes: Closes gaps, bridges, and damaged runs that waste energy.

Comfort/Safety: Improves ambient temps and touch-safe surfaces.

Rebates: Utility-incentive documentation when available.

Execution: Minimal-downtime plans and staged installation.

Insulation Removal & Replacement

Safe abatement and turnkey reinstall for wet, damaged, or outdated systems—restoring performance, compliance, and clean aesthetics.

Controls: Contained removal, proper handling, and disposal per regulations.

Root Cause: Moisture/CUI investigation to prevent repeat failures.

Prep & Coat: Surface prep and corrosion protection before new insulation.

Right-Sizing: New materials and thickness selected to today’s specs.

Weather-Tight: New cladding, seams, and terminations sealed against ingress.

Closeout: Final inspection, punch list, and as-built documentation.

Happy Customers

Projects Completed

Equipment Items Insulated

Roof Sections Restored

Message From CEO

To Our Customers

For more than 40 years, Thermal Corrosion Solutions has helped industrial and commercial facilities protect assets, control energy loss, and stop corrosion. When traditional insulation fails, we deliver proven alternatives—ceramic thermal coatings, roof & envelope restorations, piping/tank/HVAC insulation, CUI mitigation, and turnkey removal & replacement. Our promise is simple: work safely, meet spec, minimize downtime, and stand behind the result. Thank you for trusting our team across the greater Washington, Baltimore Metro, and Northern Virginia region.

Allen Hoover

Chairman and founder

TESTIMONIALS

What others are saying

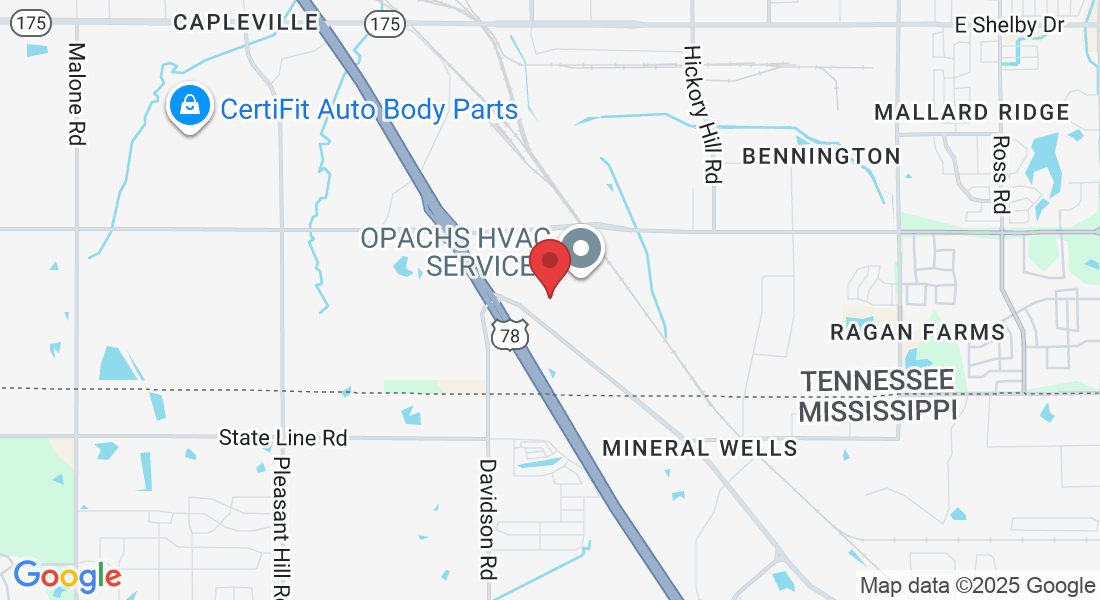

Company: Thermal Corrosion Solutions

Phone: (901) 674-1896

Address: 5534 United Dr, Memphis, TN 38118

Website: www.thermalcorrosionsolutions.com

HOURS OF OPERATION

Monday-Friday: 8am - 5pm

Saturday-Sunday: Closed

© Copyright 2026. Thermal Corrosion Solutions, LLC. All Rights Reserved.